Related Products

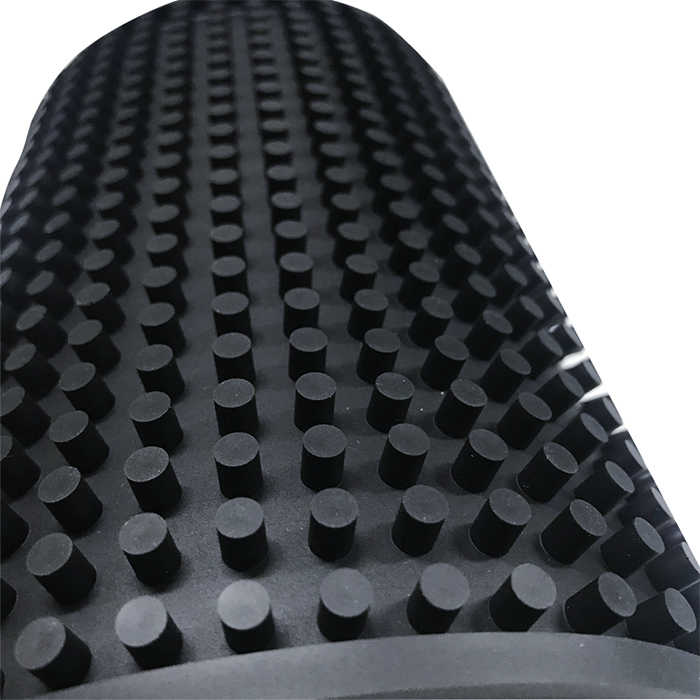

| Model: | Bar spill mat |

|---|---|

| MOQ: | 500 PCS |

| Payment: | Paypal, T/T, visa, L/C, west union, D/P, D/A, MoneyGram |

| Delivery Time: | Normally 15-20 days, big order would be a little long |

| Start Port: | Shenzhen, Guangzhou or any port in China |

| Certification: | Reach, RoHS, EN-71, CE and PAHs |

| Material: | pvc |

| Color | black, white, blue, yellow, pink, purple, orange and so on |

| Size | 600*100mm, 580*130mm or custom size |

| Thickness | 5mm-13mm |

Copyright © 2025 Tigerwings Rubber& Plastic Product Manufactory | All Rights Reserved